An efficient & innovative solution

- Simultaneously removes Sulfur Oxides (SOx) & Nitric Oxides (NOx)

- Removes Volatile Organic Compounds (VOC), Dioxins…

- Dry process

- No CO2 emission, no polluted effluent, no sludge...

- No required catalyst

- Highly valuable by-product

- Adjustable treatment as function of gas flow or treatment objectives

- Treated flow gas up to 300.000 Nm3/h

A global solution for flue gas treatment

The principle of flue gas treatment by Electron Processing System is based on the conversion of the pollutants coming

An efficient & innovative solution

- Simultaneously removes Sulfur Oxides (SOx) & Nitric Oxides (NOx)

- Removes Volatile Organic Compounds (VOC), Dioxins…

- Dry process

- No CO2 emission, no polluted effluent, no sludge...

- No required catalyst

- Highly valuable by-product

- Adjustable treatment as function of gas flow or treatment objectives

- Treated flow gas up to 300.000 Nm3/h

A global solution for flue gas treatment

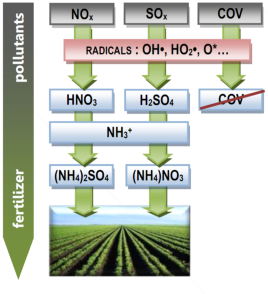

The principle of flue gas treatment by Electron Processing System is based on the conversion of the pollutants coming from combustion reactions into high valuable products for agriculture:

from combustion reactions into high valuable products for agriculture:  Electron beam treatment of flue gas leads to the formation of highly reactive entities called radicals. These radicals

Electron beam treatment of flue gas leads to the formation of highly reactive entities called radicals. These radicals simultaneously decompose organic compounds (VOC, dioxin…) and convert sulfur and nitric oxides into sulfuric and

simultaneously decompose organic compounds (VOC, dioxin…) and convert sulfur and nitric oxides into sulfuric and nitric acids respectively. Ammonia addition neutralizes these acids into ammonium sulfate and ammonium nitrate salts

nitric acids respectively. Ammonia addition neutralizes these acids into ammonium sulfate and ammonium nitrate salts that can be use as fertilizer for agriculture.

that can be use as fertilizer for agriculture.  Electron beam process can achieve high removal rates of SOX, NOX, dioxins & COV (up to 95%) which puts this

Electron beam process can achieve high removal rates of SOX, NOX, dioxins & COV (up to 95%) which puts this technology among the most efficient one for flue gas treatment on the market.

technology among the most efficient one for flue gas treatment on the market.  A large range of applications

- Incinerators

- Industrial processes

- Combustion engines

- Petrochemical industry

- Fossil-fuel power stations

© EVHeO

A large range of applications

- Incinerators

- Industrial processes

- Combustion engines

- Petrochemical industry

- Fossil-fuel power stations

© EVHeO

Consulting & Engineering Office

Environmental Applications of Electron Processing Systems

Consulting & Engineering Office

Environmental Applications of Electron Processing Systems